Series 2DAL

Modular head automatic disc filter (air and water cleaning)

- INDUSTRY. Wide range of applications for the steel, paper, automotive, cooling tower, and chemical industries…

- MUNICIPAL. Processes for wastewater treatment plants, water treatment, landscaping, and desalination…

- IRRIGATION. For drip irrigation, sprinkler irrigation, fertigation, and greenhouse irrigation…

General features

- DISC FILTRATION. Maximum safety. Its patented design and manufacturing guarantee high-quality filtration, offering a long service life thanks to its durability.

- THE PROPELLER EFFECT optimizes filtration and reduces the frequency of backwashing and maintenance.

- SELF-CLEANING FILTER ELEMENT performs the backwash phase using the minimum volume of water, maintaining an efficient cleaning action. Large filter surface area.

- WATER AND ENERGY SAVINGS, using minimal backwash pressure for maximum filter efficiency, optimizing water consumption.

- VERSATILITY, compatibility, easy maintenance. The system allows a wide range of flow rates and configurations using a minimum number of components.

- EASY transport and installation, assembled equipment.

- LOW MAINTENANCE, no tools required. Maximum durability, with moving parts not susceptible to wear during operation.

- CONFIGURABLE MODULES. Modules can be designed and configured at the customer’s request. All cartridges and accessories are interchangeable.

The air-assisted backwash system, designed for applications with large amounts of organic particles, guarantees much more efficient automatic cleaning of the filter media with lower water consumption.

IRRIFILTERS DISC AUTOMATIC: Self-cleaning disc systems composed of 2″ filter batteries with disc filter elements.

The 2DAL SERIES is the filtration range based on minimum maintenance and maximum filtration.

Excellent Filtration: As water enters the filter, it encounters the cyclonic disc, creating a centrifugal movement that removes particles from the discs. The depth filtration process is carried out through the discs.

Backwash: Cleaning is performed in counterflow, separating the discs and causing them to rotate at high speed. The combination of both effects loosens dirt, supported by the impact of high-pressure tangential jets and the impact of air from a tank on the disc surfaces. Washing occurs with a small volume of water, aided by the impact of the air, with an uninterrupted supply of filtered water.

Wide filtration ranges: modules can be designed and configured at the customer’s request.

Materials

- Body: Reinforced polyamide.

- Monoblock structure: Reinforced polyamide.

- Collectors: High-density polyethylene (HDPE).

- Gaskets: 60° Shore synthetic nitrile rubber.

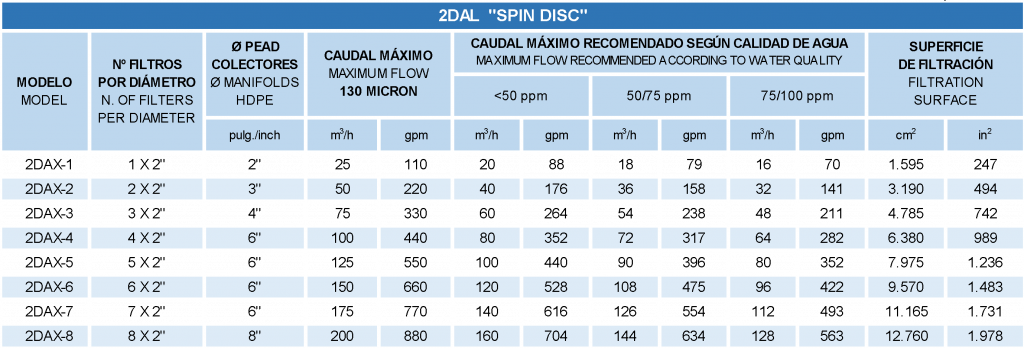

Technical specifications.