Serie MH-VE

Automatic Hydraulic mesh filter

General features

Energy Efficiency: Low water and energy consumption during the wash cycle.

Wide range: From 2″ to 6″

Easy maintenance: Convenient lid opening and easy access to the mesh.

Time saving: The filtration process continues simultaneously with the wash cycle.

Easy installation: Filters are delivered ready for installation.

Construction materials: High-quality for greater durability.

Suction nozzles: Designed for more effective suction.

Scanner: Designed for greater durability of the rotating sleeves.

CONTROL UNITS

- Wash logs

- Outlet/inlet pressure control

- Wash frequency

- Alarms with event information

- current battery status

Mod TAL-GIL

DC/AC

Mod BACCARA DFC

DC

Mod BACCARA Octupus

DC

Technical sheet

SYSTEM

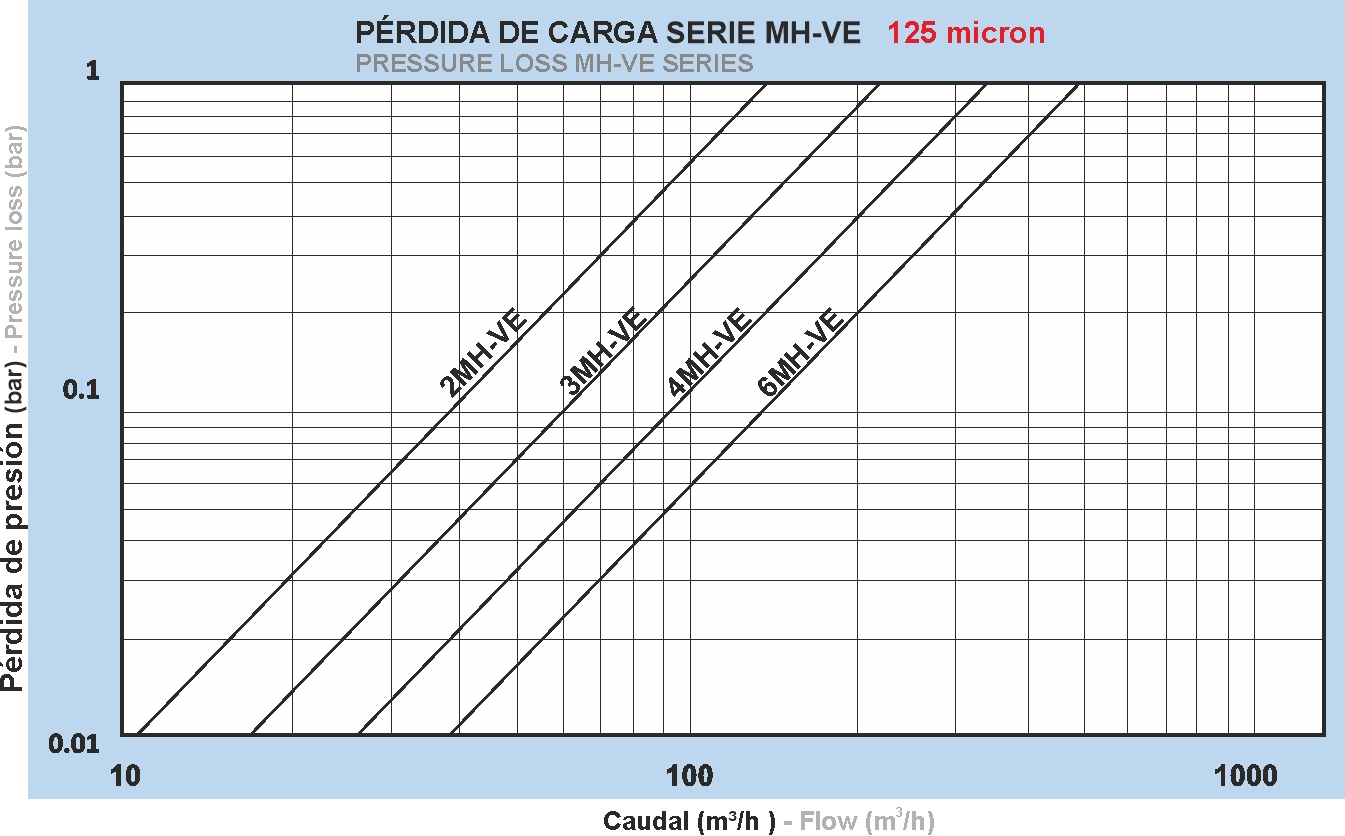

Filtration produced by the retention of larger particles within the mesh gap. Large filtering surface and minimal pressure loss.

CONSTRUCTION MATERIALS

- Body: Carbon steel.

- Mesh: AISI 316 stainless steel

- Mesh support: Injected polypropylene

- Scanner: AISI 304 stainless steel

- Suction nozzles: PVC

- Piston: High-density polyethylene sleeve

- Shaft: AISI 304 stainless steel

- Seals: 60° Shore nitrile synthetic rubber

- Screws: Zinc-plated

SURFACE TREATMENT OF STEEL

The carbon steel elements receive internal and external treatment with a pre-shot blasting of the surface grade SA-2.5, then are pre-treated with phosphate before undergoing electrostatic painting with several layers of epoxy-polyester powder paint.

FILTER ELEMENT

Stainless steel mesh injected directly into the polyamide cartridge, with filtration rates between 50 and 1000 microns, for our filters with a filtration surface area of 1,180 to 4,720 cm².

CLEANING

In the hydraulic system, the filter cartridge is cleaned automatically, ensuring the supply of filtered water, with the help of a set of suction nozzles that sweep over the entire surface of the dirty mesh.

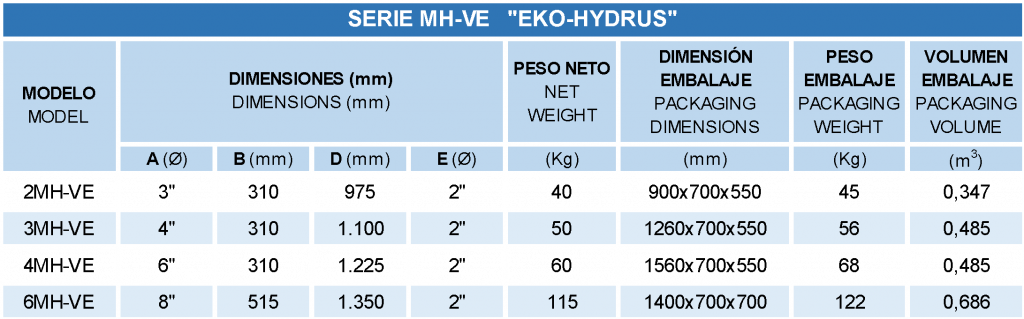

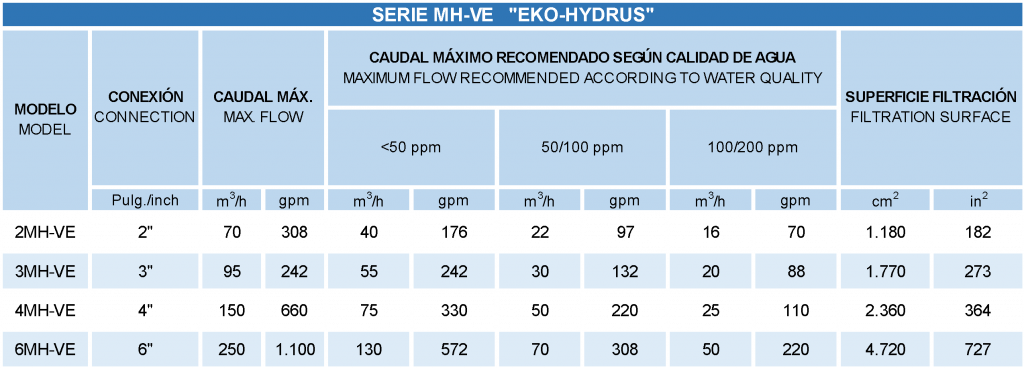

Technical specifications

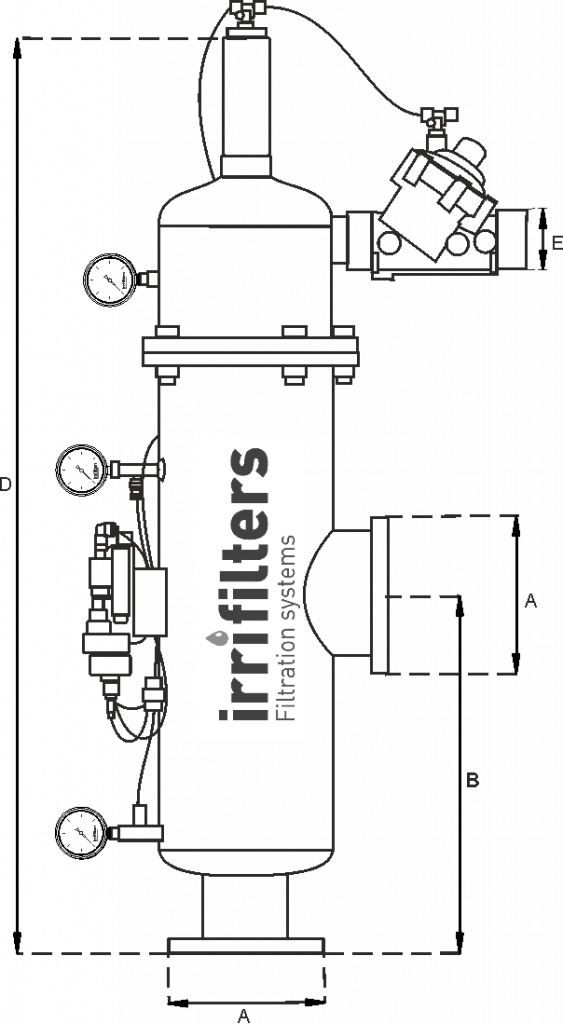

Dimensions and Weights